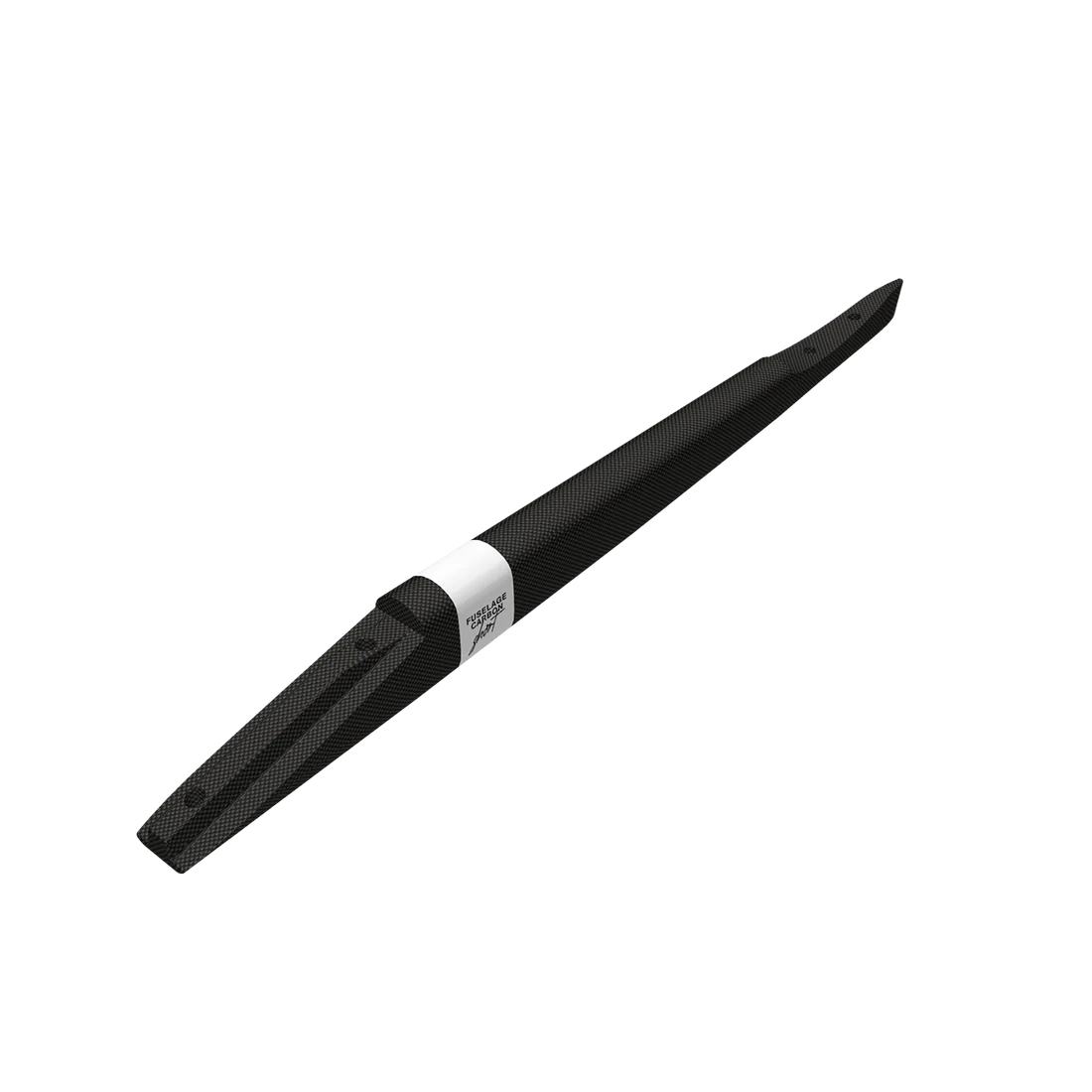

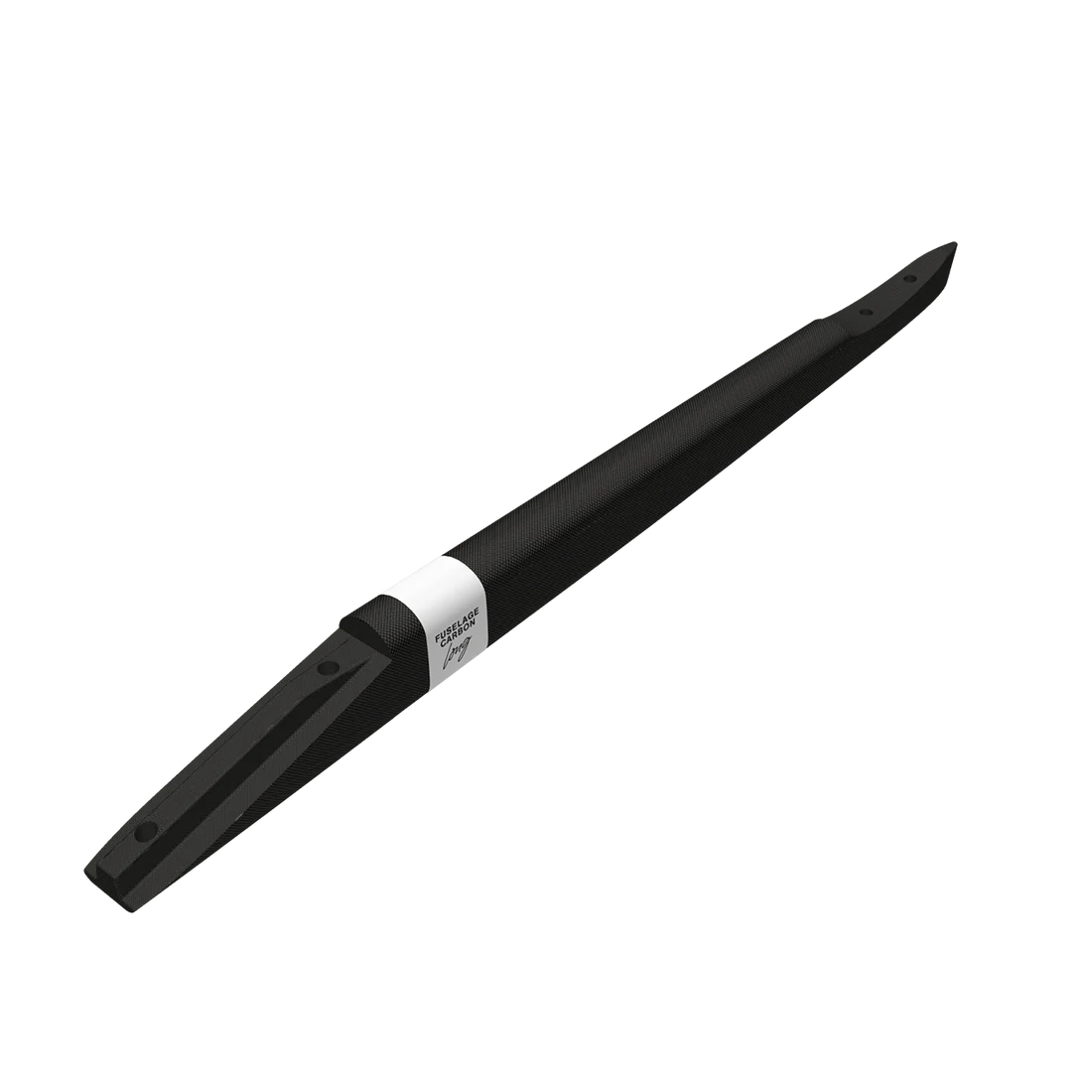

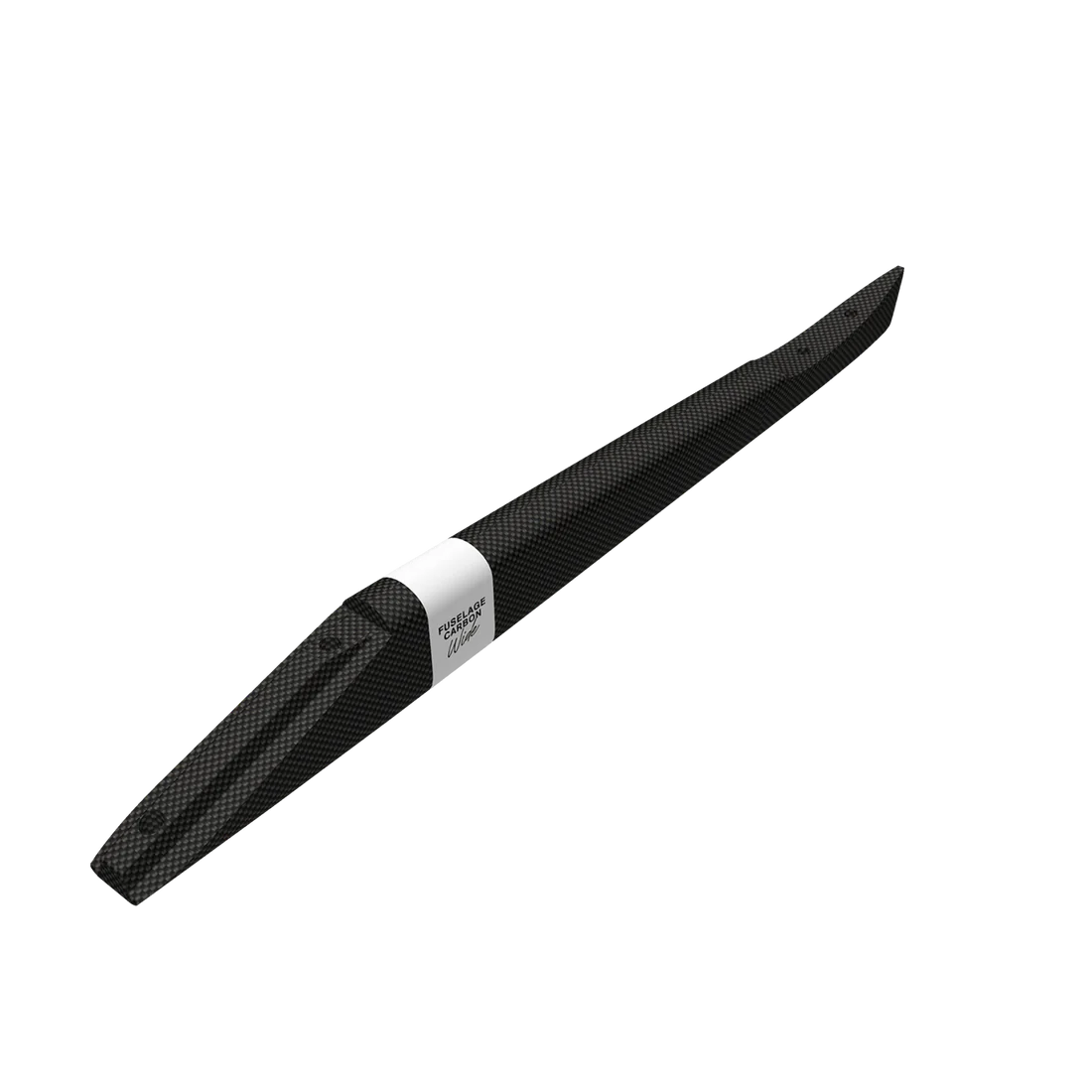

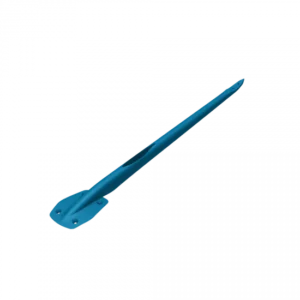

FUSELAGE CARBON

Price range: €130.00 through €145.00

Description

Technical Specifications

| FUSELAGE | CARBON X-SHORT |

| FW | PHANTOM CARBON 1280 |

| STAB | C275 SURF |

Our carbon fuselages are available in different sizes. A longer fuselage will bring more stability, while a shorter fuselage will help with sharp and quick turns.

The FUSELAGE CARBON is an essential complement to the F-ONE Monobloc carbon wings. It connects with the front wing behind the TITAN mast slot in an area where the loads are reduced. Still, the shape of the connection is inspired from the TITAN design and offers a very robust and stiff assembly. At the back, the cradle for the stabilizer is designed with the right angle to make the front wing fly with ease and efficiency.

The FUSELAGE CARBON is built in pre-preg carbon with a foam core to keep the weight extremely light. Some solidly anchored brass inserts are used for all fastenings.

- Best maneuverability

- Better responsiveness

- Ultra-light carbon construction

This fuselage is recommended with the GRAVITY CARBON range. Our carbon fuselages are available in different sizes. A longer fuselage will bring more stability, while a shorter fuselage will help with sharp and quick turns.

Weight: 0.20 kg

Length: 41 cm

F-One Foil Hardware Guide

| Connection | Head | Qty and Length | Diameter |

|---|---|---|---|

| FW to RW Tail Split Carbon Fuse | Recessed Star | 2 x 25mm | M6 |

| RW Stabilizer to Fuse | Recessed Star | 2 x 15mm | M6 |

| Mast to Titan Mast Foot | Recessed Star | 2 x 25mm | M6 |

| Mast to Top Plate | Recessed Star | 2 x 25mm | M6 |

| Mast to Carbon FW Fuse | Recessed Star | 3 x 30/32mm | M6 |

| Mast to Aluminum Fuse | Recessed Star | 2 x 25mm | M6 |

| Mast Plate to Board | Recessed Star | 4 x 25mm | M6 |

| FCT front wing | Recessed Star | 4 x 14mm | M6 |

| 4-Point Foil Mount Adapter Plate | Recessed Star | 4 x 15mm | M6 |

In the ever-evolving world of aerospace engineering, the demand for lightweight, durable, and high-performance materials has never been greater. Enter FUSELAGE CARBON, a revolutionary composite material designed to meet the rigorous demands of modern aviation. This product description will explore the unique features, benefits, and applications of FUSELAGE CARBON, while ensuring improved readability and SEO optimization.

What is FUSELAGE CARBON?

FUSELAGE CARBON is a high-performance composite material made from carbon fiber reinforced polymer (CFRP). This innovative material is engineered to provide exceptional strength-to-weight ratios, making it an ideal choice for aircraft fuselages. The unique properties of FUSELAGE CARBON allow it to withstand extreme conditions while maintaining structural integrity.

Key Features

-

Lightweight Composition: FUSELAGE CARBON is significantly lighter than traditional materials such as aluminum and steel. This reduction in weight leads to improved fuel efficiency and increased payload capacity.

-

High Strength: The carbon fibers used in FUSELAGE CARBON provide remarkable tensile strength. This ensures that aircraft can endure the stresses of flight without compromising safety.

-

Corrosion Resistance: Unlike metals, FUSELAGE CARBON is resistant to corrosion, which extends the lifespan of aircraft components and reduces maintenance costs.

-

Thermal Stability: FUSELAGE CARBON maintains its properties across a wide range of temperatures, making it suitable for various environmental conditions.

-

Design Flexibility: The versatility of FUSELAGE CARBON allows for complex shapes and designs, enabling engineers to create more aerodynamic and efficient aircraft.

Benefits of Using FUSELAGE CARBON

Enhanced Performance

When it comes to performance, FUSELAGE CARBON stands out. The lightweight nature of this material contributes to improved fuel efficiency, which is a critical factor in the aerospace industry. As a result, airlines can reduce operational costs while minimizing their environmental impact.

Increased Safety

Safety is paramount in aviation. FUSELAGE CARBON’s high strength and durability ensure that aircraft can withstand the rigors of flight. Additionally, the material’s resistance to corrosion and fatigue contributes to the overall safety of the aircraft, providing peace of mind for both manufacturers and passengers.

Cost-Effectiveness

While the initial investment in FUSELAGE CARBON may be higher than traditional materials, the long-term savings are significant. Reduced maintenance costs, improved fuel efficiency, and extended lifespan all contribute to a lower total cost of ownership. Consequently, airlines and manufacturers can benefit from the economic advantages of using .

Environmental Sustainability

In today’s world, sustainability is a key consideration for many industries. FUSELAGE CARBON is not only lightweight and efficient but also contributes to reduced carbon emissions. By using this advanced material, the aerospace industry can take significant steps toward a more sustainable future.

Applications of FUSELAGE CARBON

FUSELAGE CARBON is versatile and can be used in various applications within the aerospace sector. Some of the most notable applications include:

Commercial Aviation

In commercial aviation, FUSELAGE CARBON is increasingly being used in the construction of aircraft fuselages. Major manufacturers are adopting this material to enhance the performance and efficiency of their aircraft. As a result, passengers can enjoy a more comfortable flying experience with reduced fuel consumption.

Military Aviation

The military sector also benefits from the use of FUSELAGE CARBON. Military aircraft require materials that can withstand extreme conditions while maintaining performance. F-One Carbon Fuselage Long strength and durability make it an ideal choice for fighter jets, transport aircraft, and unmanned aerial vehicles (UAVs).

Space Exploration

As space exploration continues to advance, the need for innovative materials becomes even more critical. F-One Carbon Fuselage Long is being explored for use in spacecraft and satellites due to its lightweight and high-strength properties. This material can help reduce launch costs and improve the overall performance of space missions.

Drones and UAVs

The rise of drones and UAVs has created a demand for lightweight and durable materials. FUSELAGE CARBON is perfectly suited for these applications, providing the necessary strength without adding unnecessary weight. This allows for longer flight times and improved maneuverability.

The Manufacturing Process of FUSELAGE CARBON

The production of F-One Carbon Fuselage Long involves several key steps, ensuring that the final product meets the highest standards of quality and performance.

Material Selection

The first step in the manufacturing process is the selection of high-quality carbon fibers and resin systems. These materials are chosen based on their specific properties, ensuring that the final product will meet the desired performance criteria.

Layup Process

Once the materials are selected, the layup process begins. Layers of carbon fiber are carefully arranged and impregnated with resin. This process can be done manually or using automated systems, depending on the complexity of the part being produced.

Curing

After the layup is complete, the composite material is cured. This process involves applying heat and pressure to the material, allowing the resin to harden and bond the carbon fibers together. The curing process is critical for achieving the desired strength and performance characteristics.

Quality Control

Quality control is an essential part of the manufacturing process. Each batch of FUSELAGE CARBON undergoes rigorous testing to ensure that it meets industry standards. This includes testing for strength, durability, and resistance to environmental factors.

Why Choose FUSELAGE CARBON?

Proven Track Record

F-One Carbon Fuselage Long has been successfully used in various aerospace applications, demonstrating its reliability and performance. Many leading aircraft manufacturers have adopted this material, further validating its effectiveness.

Expert Support

When you choose FUSELAGE CARBON, you gain access to a team of experts who are dedicated to supporting your needs. From material selection to design assistance, our team is here to help you make the most of this innovative material.

Custom Solutions

Every aerospace project is unique, and F-One Carbon Fuselage Long can be tailored to meet your specific requirements. Whether you need a custom formulation or a specific design, our team can work with you to create the perfect solution.

What is FUSELAGE CARBON?

FUSELAGE CARBON is a high-performance composite material made from carbon fiber reinforced polymer (CFRP). This innovative material is engineered to provide exceptional strength-to-weight ratios, making it an ideal choice for aircraft fuselages. The unique properties of FUSELAGE CARBON allow it to withstand extreme conditions while maintaining structural integrity.

Key Features

-

Lightweight Composition: FUSELAGE CARBON is significantly lighter than traditional materials such as aluminum and steel. This reduction in weight leads to improved fuel efficiency and increased payload capacity.

-

High Strength: The carbon fibers used in FUSELAGE CARBON provide remarkable tensile strength. This ensures that aircraft can endure the stresses of flight without compromising safety.

-

Corrosion Resistance: Unlike metals, FUSELAGE CARBON is resistant to corrosion, which extends the lifespan of aircraft components and reduces maintenance costs.

-

Thermal Stability: FUSELAGE CARBON maintains its properties across a wide range of temperatures, making it suitable for various environmental conditions.

-

Design Flexibility: The versatility of FUSELAGE CARBON allows for complex shapes and designs, enabling engineers to create more aerodynamic and efficient aircraft.

Benefits of Using FUSELAGE CARBON

Enhanced Performance

When it comes to performance, FUSELAGE CARBON stands out. The lightweight nature of this material contributes to improved fuel efficiency, which is a critical factor in the aerospace industry. As a result, airlines can reduce operational costs while minimizing their environmental impact.

Increased Safety

Safety is paramount in aviation. FUSELAGE CARBON’s high strength and durability ensure that aircraft can withstand the rigors of flight. Additionally, the material’s resistance to corrosion and fatigue contributes to the overall safety of the aircraft, providing peace of mind for both manufacturers and passengers.

Cost-Effectiveness

While the initial investment in FUSELAGE CARBON may be higher than traditional materials, the long-term savings are significant. Reduced maintenance costs, improved fuel efficiency, and extended lifespan all contribute to a lower total cost of ownership. Consequently, airlines and manufacturers can benefit from the economic advantages of using

Environmental Sustainability

In today’s world, sustainability is a key consideration for many industries. FUSELAGE CARBON is not only lightweight and efficient but also contributes to reduced carbon emissions. By using this advanced material, the aerospace industry can take significant steps toward a more sustainable future.

Applications of FUSELAGE CARBON

FUSELAGE CARBON is versatile and can be used in various applications within the aerospace sector. Some of the most notable applications include:

Commercial Aviation

In commercial aviation, FUSELAGE CARBON is increasingly being used in the construction of aircraft fuselages. Major manufacturers are adopting this material to enhance the performance and efficiency of their aircraft. As a result, passengers can enjoy a more comfortable flying experience with reduced fuel consumption.

Military Aviation

The military sector also benefits from the use of FUSELAGE CARBON. Military aircraft require materials that can withstand extreme conditions while maintaining performance. FUSELAGE CARBON’s strength and durability make it an ideal choice for fighter jets, transport aircraft, and unmanned aerial vehicles (UAVs).

Space Exploration

As space exploration continues to advance, the need for innovative materials becomes even more critical. FUSELAGE CARBON is being explored for use in spacecraft and satellites due to its lightweight and high-strength properties. This material can help reduce launch costs and improve the overall performance of space missions.

Drones and UAVs

The rise of drones and UAVs has created a demand for lightweight and durable materials. FUSELAGE CARBON is perfectly suited for these applications, providing the necessary strength without adding unnecessary weight. This allows for longer flight times and improved maneuverability.

Emerging Technologies

FUSELAGE CARBON is also paving the way for emerging technologies in the aerospace sector. As the industry moves toward electric and hybrid aircraft, the need for lightweight materials becomes even more pronounced. FUSELAGE CARBON can play a crucial role in the development of these next-generation aircraft, enabling longer ranges and more efficient operations.

The Manufacturing Process of FUSELAGE CARBON

The production of FUSELAGE CARBON involves several key steps, ensuring that the final product meets the highest standards of quality and performance.

Material Selection

The first step in the manufacturing process is the selection of high-quality carbon fibers and resin systems. These materials are chosen based on their specific properties, ensuring that the final product will meet the desired performance criteria.

Layup Process

Once the materials are selected, the layup process begins. Layers of carbon fiber are carefully arranged and impregnated with resin. This process can be done manually or using automated systems, depending on the complexity of the part being produced.

Curing

After the layup is complete, the composite material is cured. This process involves applying heat and pressure to the material, allowing the resin to harden and bond the carbon fibers together. The curing process is critical for achieving the desired strength and performance characteristics.

Quality Control

Quality control is an essential part of the manufacturing process. Each batch of

F-One Carbon Fuselage Long undergoes rigorous testing to ensure that it meets industry standards. This includes testing for strength, durability, and resistance to environmental factors.

Importance of FUSELAGE CARBON in the Aerospace Industry

Meeting Regulatory Standards

The aerospace industry is heavily regulated, with strict standards governing materials used in aircraft construction. FUSELAGE CARBON not only meets but often exceeds these regulatory requirements. This compliance ensures that manufacturers can confidently use this material in their designs, knowing that it adheres to safety and performance standards.

Innovation and Research

FUSELAGE CARBON is at the forefront of research and innovation in aerospace materials. Ongoing studies are exploring new formulations and applications, which could further enhance its properties. As the industry continues to evolve, FUSELAGE CARBON will likely play a pivotal role in the development of next-generation aircraft and technologies.

Global Competitiveness

As the aerospace market becomes increasingly competitive, manufacturers must seek ways to differentiate themselves. By incorporating FUSELAGE CARBON into their designs, companies can offer lighter, more efficient, and safer aircraft. This competitive edge can lead to increased market share and profitability.

Collaboration and Partnerships

The introduction of FUSELAGE CARBON has fostered collaboration between material scientists, engineers, and manufacturers. This synergy is essential for driving innovation and ensuring that the aerospace industry continues to advance. By working together, stakeholders can explore new applications and improve existing technologies.

Why Choose FUSELAGE CARBON?

Proven Track Record

FUSELAGE CARBON has been successfully used in various aerospace applications, demonstrating its reliability and performance. Many leading aircraft manufacturers have adopted this material, further validating its effectiveness.

Expert Support

When you choose F-One Carbon Fuselage Long, you gain access to a team of experts who are dedicated to supporting your needs. From material selection to design assistance, our team is here to help you make the most of this innovative material .

Custom Solutions

Every aerospace project is unique, and F-One Carbon Fuselage Long can be tailored to meet your specific requirements. Whether you need a custom formulation or a specific design, our team can work with you to create the perfect solution.

Future-Proofing Your Aircraft

Investing in FUSELAGE CARBON is not just about immediate benefits; it’s also about future-proofing your aircraft. As the industry shifts toward more sustainable and efficient technologies, FUSELAGE CARBON will remain a relevant and valuable material choice. F-One Carbon Fuselage Long

Conclusion

In conclusion, F-One Carbon Fuselage Long represents a significant advancement in aerospace materials. Its lightweight composition, high strength, and durability make it an ideal choice for a wide range of applications. By choosing FUSELAGE CARBON, manufacturers and airlines can enhance performance, increase safety, and reduce costs while contributing to a more sustainable future.

As the aerospace industry continues to evolve, F-One Carbon Fuselage Long will play a crucial role in shaping the future of aviation. With its proven track record and expert support, this innovative material is poised to become the standard for aircraft fuselages and beyond.

Explore the possibilities of FUSELAGE CARBON today and take your aerospace projects to new heights!

Additional information

| SIZE | xxx-SHORT, xx-SHORT, x-SHORT, SHORT, LONG, WIDE |

|---|

Reviews

There are no reviews yet.