MONOBLOC TAIL PUMPING

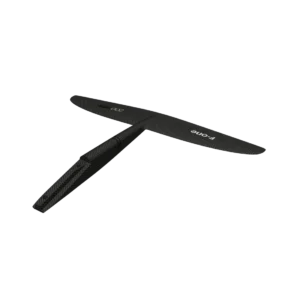

€240.00MONOBLOC TAIL PUMPING The Ultimate Solution for Efficient Fluid Management Introduction Monobloc Tail Pumping In the world of fluid management, efficiency and reliability are paramount. One of the most innovative solutions that have emerged in recent years is the Monobloc Tail Pumping system. This advanced technology is designed to optimize fluid transfer processes across various industries, including oil and gas, water treatment, and chemical processing. Monobloc Tail Pumping In this comprehensive guide, we will explore the intricacies of Monobloc Tail Pumping, its benefits, applications, and how it stands out in the competitive landscape of fluid management solutions. MONOBLOC TAIL PUMPING What is Monobloc Tail Pumping? Monobloc Tail Pumping refers to a specific type of pumping system that integrates multiple components into a single, compact unit. This design minimizes the need for additional fittings and connections, resulting in a more streamlined and efficient operation. The term “monobloc” signifies that the pump is constructed from a single block of material, which enhances durability and reduces the risk of leaks. MONOBLOC TAIL PUMPING What is the F-One Monobloc Tail Pumping System? The F-One Monobloc Tail Pumping system is an innovative pumping mechanism designed specifically for the Time 2 Wing. This system integrates a monobloc design, which means that the pump is constructed from a single piece of material, enhancing durability and performance. The Monobloc Tail Pumping system is engineered to provide optimal inflation and deflation of the wing, ensuring that riders can achieve the perfect balance of lift and control. Key Features of the F-One Monobloc Tail Pumping System Single-Block Construction: The monobloc design minimizes the risk of leaks and enhances the overall durability of the pump. Efficient Inflation: The system allows for quick and easy inflation, enabling riders to get on the water faster. Lightweight Design: The lightweight materials used in the construction of the pump make it easy to transport and handle. User -Friendly Interface: The pump features an intuitive design that simplifies the inflation process, making it accessible for riders of all skill levels. Versatile Compatibility: While designed for the Time 2 Wing, the Monobloc Tail Pumping system can be adapted for use with other F-One products, enhancing its utility. Benefits of the F-One Monobloc Tail Pumping System 1. Enhanced Performance The F-One Monobloc Tail Pumping system is engineered to optimize the performance of the Time 2 Wing. With efficient inflation, riders can achieve the ideal wing shape, resulting in improved lift, stability, and control on the water. 2. Time-Saving Design Inflating your wing quickly means more time on the water. The Monobloc Tail Pumping system allows for rapid inflation and deflation, enabling riders to spend less time preparing and more time enjoying their sessions. 3. Durability and Reliability Constructed from high-quality materials, the monobloc design ensures that the pump can withstand the rigors of water sports. This durability translates to a longer lifespan and reduced need for replacements or repairs. 4. Lightweight and Portable The lightweight nature of the F-One Monobloc Tail Pumping system makes it easy to carry to and from the water. This portability is essential for riders who travel frequently or need to transport their gear. 5. User-Friendly Operation The intuitive design of the pump makes it easy for both beginners and experienced riders to operate. Clear instructions and a straightforward interface ensure that anyone can achieve optimal inflation without hassle. How to Use the F-One Monobloc Tail Pumping System Connection Head Qty and Length Diameter FW to RW Tail Split Carbon Fuse Recessed Star 2 x 25mm M6 RW Stabilizer to Fuse Recessed Star 2 x 15mm M6 Mast to Titan Mast Foot Recessed Star 2 x 25mm M6 Mast to Top Plate Recessed Star 2 x 25mm M6 Mast to Carbon FW Fuse Recessed Star 3 x 30/32mm M6 Mast to Aluminum Fuse Recessed Star 2 x 25mm M6 Mast Plate to Board Recessed Star 4 x 25mm M6 FCT front wing Recessed Star 4 x 14mm M6 4-Point Foil Mount Adapter Plate Recessed Star 4 x 15mm M6 Using the F-One Monobloc Tail Pumping system is straightforward. Follow these steps to ensure optimal performance: Prepare the Wing: Lay the Time 2 Wing flat on a clean surface, ensuring that the valves are accessible. Connect the Pump: Attach the pump nozzle securely to the wing’s inflation valve. Inflate the Wing: Begin pumping using a steady rhythm. The efficient design of the Monobloc Tail Pumping system will allow for quick inflation. Check Pressure: Once the wing is inflated, check the pressure to ensure it meets the recommended specifications. Disconnect and Secure: Remove the pump nozzle and securely close the valve to prevent air loss. Deflation: To deflate, open the valve and allow the air to escape. The lightweight design of the pump makes it easy to pack away once the wing is deflated. Applications of the F-One Monobloc Tail Pumping System 1. Kiteboarding The F-One Monobloc Tail Pumping system is ideal for kiteboarders looking to enhance their performance on the water. The efficient inflation process allows for quick setup, enabling riders to maximize their time on the water. 2. Foiling For foilers, the Time 2 Wing paired with the Monobloc Tail Pumping system offers exceptional lift and control. The ability to achieve the perfect wing shape is crucial for optimal foiling performance. 3. Recreational Water Sports Whether you’re a casual rider or a competitive athlete, the F-One Monobloc Tail Pumping system is designed to meet the needs of all water sports enthusiasts. Its versatility makes it suitable for various applications beyond Key Features of Monobloc Tail Pumping Compact Design: The monobloc construction allows for a smaller footprint, making it ideal for installations with limited space. Enhanced Durability: Made from high-quality materials, these pumps are built to withstand harsh operating conditions. Reduced Maintenance: With fewer components to manage, maintenance requirements are significantly lowered. High Efficiency: The design minimizes energy loss, leading to lower operational costs. Versatility: Suitable for a wide range of fluids, including corrosive and viscous materials. How Monobloc Tail Pumping Works The Monobloc Tail Pumping…