MONOBLOC TAIL PUMPING

€240.00

Description

MONOBLOC TAIL PUMPING

The Ultimate Solution for Efficient Fluid Management

Introduction

Monobloc Tail Pumping In the world of fluid management, efficiency and reliability are paramount. One of the most innovative solutions that have emerged in recent years is the Monobloc Tail Pumping system. This advanced technology is designed to optimize fluid transfer processes across various industries, including oil and gas, water treatment, and chemical processing.

Monobloc Tail Pumping In this comprehensive guide, we will explore the intricacies of Monobloc Tail Pumping, its benefits, applications, and how it stands out in the competitive landscape of fluid management solutions. MONOBLOC TAIL PUMPING

What is Monobloc Tail Pumping?

Monobloc Tail Pumping refers to a specific type of pumping system that integrates multiple components into a single, compact unit. This design minimizes the need for additional fittings and connections, resulting in a more streamlined and efficient operation. The term “monobloc” signifies that the pump is constructed from a single block of material, which enhances durability and reduces the risk of leaks. MONOBLOC TAIL PUMPING

What is the F-One Monobloc Tail Pumping System?

The F-One Monobloc Tail Pumping system is an innovative pumping mechanism designed specifically for the Time 2 Wing. This system integrates a monobloc design, which means that the pump is constructed from a single piece of material, enhancing durability and performance. The Monobloc Tail Pumping system is engineered to provide optimal inflation and deflation of the wing, ensuring that riders can achieve the perfect balance of lift and control.

Key Features of the F-One Monobloc Tail Pumping System

- Single-Block Construction: The monobloc design minimizes the risk of leaks and enhances the overall durability of the pump.

- Efficient Inflation: The system allows for quick and easy inflation, enabling riders to get on the water faster.

- Lightweight Design: The lightweight materials used in the construction of the pump make it easy to transport and handle.

- User -Friendly Interface: The pump features an intuitive design that simplifies the inflation process, making it accessible for riders of all skill levels.

- Versatile Compatibility: While designed for the Time 2 Wing, the Monobloc Tail Pumping system can be adapted for use with other F-One products, enhancing its utility.

Benefits of the F-One Monobloc Tail Pumping System

1. Enhanced Performance

The F-One Monobloc Tail Pumping system is engineered to optimize the performance of the Time 2 Wing. With efficient inflation, riders can achieve the ideal wing shape, resulting in improved lift, stability, and control on the water.

2. Time-Saving Design

Inflating your wing quickly means more time on the water. The Monobloc Tail Pumping system allows for rapid inflation and deflation, enabling riders to spend less time preparing and more time enjoying their sessions.

3. Durability and Reliability

Constructed from high-quality materials, the monobloc design ensures that the pump can withstand the rigors of water sports. This durability translates to a longer lifespan and reduced need for replacements or repairs.

4. Lightweight and Portable

The lightweight nature of the F-One Monobloc Tail Pumping system makes it easy to carry to and from the water. This portability is essential for riders who travel frequently or need to transport their gear.

5. User-Friendly Operation

The intuitive design of the pump makes it easy for both beginners and experienced riders to operate. Clear instructions and a straightforward interface ensure that anyone can achieve optimal inflation without hassle.

How to Use the F-One Monobloc Tail Pumping System

| Connection | Head | Qty and Length | Diameter |

|---|---|---|---|

| FW to RW Tail Split Carbon Fuse | Recessed Star | 2 x 25mm | M6 |

| RW Stabilizer to Fuse | Recessed Star | 2 x 15mm | M6 |

| Mast to Titan Mast Foot | Recessed Star | 2 x 25mm | M6 |

| Mast to Top Plate | Recessed Star | 2 x 25mm | M6 |

| Mast to Carbon FW Fuse | Recessed Star | 3 x 30/32mm | M6 |

| Mast to Aluminum Fuse | Recessed Star | 2 x 25mm | M6 |

| Mast Plate to Board | Recessed Star | 4 x 25mm | M6 |

| FCT front wing | Recessed Star | 4 x 14mm | M6 |

| 4-Point Foil Mount Adapter Plate | Recessed Star | 4 x 15mm | M6 |

Using the F-One Monobloc Tail Pumping system is straightforward. Follow these steps to ensure optimal performance:

- Prepare the Wing: Lay the Time 2 Wing flat on a clean surface, ensuring that the valves are accessible.

- Connect the Pump: Attach the pump nozzle securely to the wing’s inflation valve.

- Inflate the Wing: Begin pumping using a steady rhythm. The efficient design of the Monobloc Tail Pumping system will allow for quick inflation.

- Check Pressure: Once the wing is inflated, check the pressure to ensure it meets the recommended specifications.

- Disconnect and Secure: Remove the pump nozzle and securely close the valve to prevent air loss.

- Deflation: To deflate, open the valve and allow the air to escape. The lightweight design of the pump makes it easy to pack away once the wing is deflated.

Applications of the F-One Monobloc Tail Pumping System

1. Kiteboarding

The F-One Monobloc Tail Pumping system is ideal for kiteboarders looking to enhance their performance on the water. The efficient inflation process allows for quick setup, enabling riders to maximize their time on the water.

2. Foiling

For foilers, the Time 2 Wing paired with the Monobloc Tail Pumping system offers exceptional lift and control. The ability to achieve the perfect wing shape is crucial for optimal foiling performance.

3. Recreational Water Sports

Whether you’re a casual rider or a competitive athlete, the F-One Monobloc Tail Pumping system is designed to meet the needs of all water sports enthusiasts. Its versatility makes it suitable for various applications beyond

Key Features of Monobloc Tail Pumping

- Compact Design: The monobloc construction allows for a smaller footprint, making it ideal for installations with limited space.

- Enhanced Durability: Made from high-quality materials, these pumps are built to withstand harsh operating conditions.

- Reduced Maintenance: With fewer components to manage, maintenance requirements are significantly lowered.

- High Efficiency: The design minimizes energy loss, leading to lower operational costs.

- Versatility: Suitable for a wide range of fluids, including corrosive and viscous materials.

How Monobloc Tail Pumping Works

The Monobloc Tail Pumping system operates on the principle of positive displacement. As the pump’s rotor turns, it creates a vacuum that draws fluid into the chamber. The fluid is then pushed out through the discharge port, ensuring a consistent flow rate. This mechanism is particularly effective for applications requiring precise fluid transfer. Monobloc Tail Pumping

Components of a Monobloc Tail Pumping System

- Pump Housing: The outer shell that encases the internal components, providing protection and structural integrity. Monobloc Tail Pumping

- Rotor: The rotating element that creates the vacuum and moves the fluid.

- Stator: The stationary part that houses the rotor and helps maintain the pressure within the pump.

- Seals and Gaskets: Essential for preventing leaks and ensuring the integrity of the system.

- Drive Mechanism: The motor or engine that powers the rotor’s movement.

Benefits of Monobloc Tail Pumping

1. Increased Efficiency

One of the standout features of Monobloc Tail Pumping is its efficiency. The design minimizes energy loss, allowing for higher flow rates with lower power consumption. This efficiency translates to cost savings for businesses, making it an attractive option for fluid management.

2. Space-Saving Design

In industries where space is at a premium, the compact nature of Monobloc Tail Pumping systems is a significant advantage. These pumps can be easily integrated into existing setups without requiring extensive modifications.

3. Reduced Maintenance Costs

With fewer components and a robust design, Monobloc Tail Pumping systems require less maintenance compared to traditional pumping solutions. This reduction in maintenance not only saves time but also lowers operational costs.

4. Versatility Across Applications

Monobloc Tail Pumping systems are suitable for a wide range of applications, from transferring water to handling more complex fluids like chemicals and oils. This versatility makes them a valuable asset in various industries.

5. Enhanced Safety Features

Safety is a critical concern in fluid management. Monobloc Tail Pumping systems are designed with safety in mind, featuring robust seals and materials that can withstand high pressures and corrosive substances.

Applications of Monobloc Tail Pumping

1. Oil and Gas Industry

In the oil and gas sector, Monobloc Tail Pumping systems are used for transporting crude oil, natural gas, and other hydrocarbons. Their ability to handle viscous fluids and operate under high pressure makes them ideal for this demanding environment.

2. Water Treatment

Water treatment facilities utilize Monobloc Tail Pumping systems for the efficient transfer of water and wastewater. Their reliability and efficiency contribute to the overall effectiveness of water treatment processes.

3. Chemical Processing

The chemical industry often deals with corrosive and hazardous materials. Monobloc Tail Pumping systems are designed to handle these substances safely, ensuring that operations run smoothly without compromising safety.

4. Food and Beverage Industry

In the food and beverage sector, hygiene and safety are paramount. Monobloc Tail Pumping systems can be constructed from food-grade materials, making them suitable for transferring liquids in this industry.

5. Pharmaceutical Applications

The pharmaceutical industry requires precise fluid management to ensure product quality. Monobloc Tail Pumping systems provide the accuracy and reliability needed for this critical application.

Technical Specifications

HM

The High Modulus Carbon fiber layup is 1.5x stiffer than the regular carbon fiber used in other constructions. The percentage of high modulus fiber has been carefully adjusted to obtain the best stiffness in both bending and torsion while keeping enough comfort for any kind of practice.

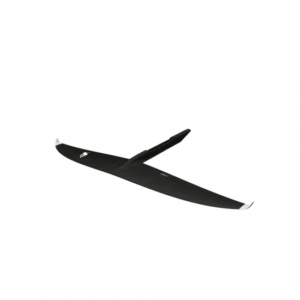

MONOBLOC TAIL

The monobloc construction improves stiffness and reduces turbulence by eliminating connections and providing a more streamlined design. This premium connection will make any foil more playful, more stable, and faster. The monobloc also removes two screws; you’ll be on the water faster!

The connection of the front wing with the fuselage is highly stressed and loaded, so it is one of the critical areas of the assembly in terms of structures.

The Monobloc front wings are molded together with the fuselage in one shot, thereby removing the connection and the chances for unwanted and parasitic movements.

The structural fibers of the fuselage are spread into the wing to achieve the smoothest and lightest connection.

It is also incredibly stiff and provides absolute control at all times, with the foil responding perfectly to all of the riders’ input.

When the overall dimensions are too large for convenient transportation, a connection is set into the fuselage, behind the mast where the loads are smaller.

What is the Monobloc Tail Pumping System?

The Monobloc Tail Pumping System is a compact, integrated pumping unit that is designed for a wide range of applications. Its monobloc design means that the pump and motor are combined into a single unit, which not only saves space but also simplifies installation and maintenance. This system is engineered to handle various fluids, including water, chemicals, and slurries, making it a versatile choice for any operation.

Key Features

-

Compact Design: The monobloc configuration allows for a smaller footprint, making it ideal for installations where space is limited. This design also reduces the number of components, leading to fewer potential points of failure.

-

High Efficiency: The Monobloc Tail Pumping System is designed to operate at peak efficiency, minimizing energy consumption while maximizing output. This efficiency translates to lower operational costs and a reduced environmental impact.

-

Durable Construction: Built with high-quality materials, the Monobloc Tail Pumping System is engineered to withstand harsh conditions. Its robust construction ensures longevity and reliability, even in demanding environments.

-

Easy Installation: The integrated design simplifies the installation process, allowing for quick setup and minimal downtime. The system comes with comprehensive installation instructions, making it accessible for both professionals and DIY enthusiasts.

-

User -Friendly Operation: The Monobloc Tail Pumping System features intuitive controls that make it easy to operate. Users can quickly adjust settings and monitor performance, ensuring optimal operation at all times.

-

Versatile Applications: This pumping system is suitable for a wide range of applications, including irrigation, drainage, wastewater management, and industrial processes. Its adaptability makes it a valuable asset for various industries.

-

Low Maintenance: With fewer moving parts and a robust design, the Monobloc Tail Pumping System requires minimal maintenance. Regular checks and basic upkeep are all that is needed to keep the system running smoothly.

-

Safety Features: Safety is a top priority in the design of the Monobloc Tail Pumping System. It includes built-in safety features such as thermal overload protection and automatic shut-off mechanisms to prevent damage and ensure safe operation.

Benefits of the Monobloc Tail Pumping System

-

Cost-Effective: The high efficiency and low maintenance requirements of the Monobloc Tail Pumping System lead to significant cost savings over time. Users can expect a quick return on investment due to reduced energy bills and maintenance costs.

-

Environmentally Friendly: By consuming less energy and reducing waste, the Monobloc Tail Pumping System is an environmentally responsible choice. Its design aligns with modern sustainability goals, making it suitable for eco-conscious businesses.

-

Enhanced Performance: The advanced engineering of the Monobloc Tail Pumping System ensures consistent performance, even under varying conditions. Users can rely on this system to deliver reliable results, enhancing overall productivity.

-

Scalability: As businesses grow and their needs change, the Monobloc Tail Pumping System can easily adapt. Its versatile design allows for scalability, making it a long-term solution for fluid management.

Applications

The Monobloc Tail Pumping System is ideal for a variety of applications, including:

-

Agriculture: Efficiently manage irrigation systems, ensuring crops receive the necessary water supply while conserving resources.

-

Construction: Handle dewatering tasks on construction sites, preventing water accumulation and ensuring safe working conditions.

-

Municipal Services: Support wastewater treatment facilities and stormwater management systems, contributing to effective urban infrastructure.

-

Industrial Processes: Facilitate the movement of chemicals and slurries in manufacturing and processing plants, ensuring smooth operations.

Customer Testimonials

Don’t just take our word for it! Here’s what some of our satisfied customers have to say about the Monobloc Tail Pumping System:

-

John D., Agricultural Manager: “The Monobloc Tail Pumping System has transformed our irrigation process. It’s efficient, easy to use, and has significantly reduced our water usage.”

-

Sarah L., Construction Supervisor: “We installed the Monobloc system on our site, and it has made a world of difference. It’s compact, powerful, and has handled all our dewatering needs without a hitch.”

-

Michael T., Facility Manager: “The reliability of the Monobloc Tail Pumping System is unmatched. We’ve had zero downtime since installation, and the energy savings are impressive.”

Reviews

There are no reviews yet.